LIDS (a) In pottery.

LIDS can be made by slip casting or throwing, throwing is explained here.

LID is the top part of a jar, basin, jug, box, etc. that is separate and is used for different purposes, visual, hygienic and to help keep contents at a required temperature. It should be thought of as part of the shape and design as a whole, the two parts, lid and body, should complement each other. Both should be made at the same time, so that the shrinking of the clay proceeds at the same rate, thus helping to ensure they fit together correctly.

The drawings above illustrate the many possible shapes of lid.

The drawings above illustrate the many possible shapes of lid.

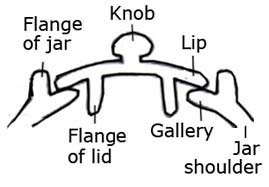

The diagram above shows the different sections of the lid.

Flange of the jar: A ridge on the lid and neck of a jar formed to control the movement of the lid and stop it slipping off.

Knob: A small protruding, round piece of clay on the top of a lid, side of a bowl or jar, used as a decoration and to hold when picking the lid up.

Shoulder: The turning point where the shoulder joins the neck.

Neck: The part that narrows before joining the flange of the jar.

Gallery: The part of the shoulder or neck that supports the lid.

Flange of the lid: The part the lid stands on when taken off the jar and which holds it in place.

Lip of lid: Can overlap the flange of the jar or be inside it and rest on the gallery. It is designed to fit exactly so it cannot slip off and it keeps the ingredients it is carrying hot. This is shown in the first two of the eight drawings at the top.

LIDS IN RELATION TO JARS

The drawings show three types of lid and all have many variants. The first lid rests on the flange, the second rests on a gallery inside the neck and in the last drawing the lid of the lip rests directly on top of the flange.

Lids are always used as part of other utensils such as jars, pots and casseroles. The main body is made first so the lid can be made to fit. There are two ways of turning a lid, the first is by working directly on top of the wheel and the other using a cone. A cone is usually used when a longer shape is needed or a knob has to form an integral part of the lid. Lids that are made using a wheel are always formed upside-down and have to be turned. The two methods are explained in the following sections.

The next section; Lids (b) Selection of lids