ABRASER

ca: ABRASÍMETRE

es: ABRASÍMETRO

Abraser is a machine used to determine the abrasion resistance of a material. It is a strong steel cylinder that rotates and carries heavy, strong, balls which fall and break down the product being tested.

ca: ABRASÍMETRE

es: ABRASÍMETRO

Abraser is a machine used to determine the abrasion resistance of a material. It is a strong steel cylinder that rotates and carries heavy, strong, balls which fall and break down the product being tested.

ca: ABRASIUS

es: ABRASIVOS

Abrasives are materials used for grinding, polishing and sandpapering. Extremely strong ceramic wares that can be fired at very high temperatures produce surfaces which are resistant to abrasion. The components of glazed ware most resistant to abrasion are alumina (Al²O³) and silica (SiO²).

ca: ABSORBÈNCIA

es: ABSORBENCIA

Absorbency describes the rate at which a body of material (clay unfired and fired, plaster, wood, stone, etc.) will soak up moisture.

es: ABSORCIÓN – En la arcilla.

Absorption is the process by which two or more products combine. In clay, the absorption of dampness makes it expand and increases its weight, which leads to cracking and breaking. Clay is not completely dry at room temperature. If fired up to 120º C to dry off and then left to cool, it will be able to reabsorb more dampness. If firing clay of different thicknesses, the first firing should be long with the temperature rising slowly, so the clay can dry out completely before becoming bisque at 600º C.

Read more about: Clay

ca: ÀCID

es: ÁCIDO

Acid; acidic oxides

In pottery, acids are used in slips and glazes.

In chemistry it is a compound usually having a sour taste and capable of neutralizing alkalis and reddening blue litmus paper, also containing hydrogen that can be replaced by a metal or an electropositive group to form a salt, or containing an atom that can accept a pair of electrons from a base. Acids are proton donors that yield hydronium ions in water solutions, or electron-pair acceptors that combine with electron-pair donors or bases.

ca: ADDITIUS – Ceràmic materials.

es: ADITIVOS – Cerámic Materiales.

Additives are different pottery materials that have to be added to clay when in its natural state and while being manufactured, to make it pliable.

Grogs, sand and other materials can be added to clay to give strength, textures, improve colors and avoid shrinking. Combustible materials, rice, pasta, dried plants, etc. can be added to the clay so that during firing they will burn away, leaving a texture. Sand and grog of different colors and textures can be broken down and added. These do not burn away but give texture and strengthen the clay when fired.

Grogs can be made from different types of crushed red brick. If you sandpaper or use an electric saw for cutting and filing tiles, this will throw off very fine grog that can be used. Always make sure that what is to be added can be fired up to the same temperature as the clay being used, because like all clays, if over fired it will melt and bleed.

When certain clay colors are required, body stains can be purchased in powder form and mixed into the clay. It is always better to mix these with white clay as the color of the clay can affect the stains.

Read more about: Grog

ca: ADHERIR-SE

es: ADHERIRSE

Adhere in pottery refers to how different products when put together can be made to stay in place and do not run. When adding colors to a fired, glazed surface, a natural glue product can be used to make them adhere. A thin layer is brushed over the surface to keep the colors in place and when the object is fired, the glue burns away.

ca: ADHESIU

es: ADHESIVO

Adhesive is a substance, such as glue or glaze that causes one object to adhere to another. Glue can be laid over bisque and a fired glaze can act as a binder. Cover a fired glaze with a thin layer of glue and leave it to dry. It can then be painted, which stops the colors crawling. The base of glues used must be natural so that they burn away when fired. glue – Arabic is the one most used.

Read more about: On-glaze – Third firing

Agate is a stone with many colors. Agateware is named after it and implies different colored clays being mixed together. They can be mixed by kneading to create random effects or in separate pieces of different colors to build up a previously planned pattern. Agateware bowls can be created using press or hump molds and agateware tiles by using different shaped frames. Use white or a clear colored clay and add body stains to get the color you require or use colored clays that can be bought. It is always better to use the same type and make, as mixing different ones can cause problems such as shrinking in different proportions.

Agate is a stone with many colors. Agateware is named after it and implies different colored clays being mixed together. They can be mixed by kneading to create random effects or in separate pieces of different colors to build up a previously planned pattern. Agateware bowls can be created using press or hump molds and agateware tiles by using different shaped frames. Use white or a clear colored clay and add body stains to get the color you require or use colored clays that can be bought. It is always better to use the same type and make, as mixing different ones can cause problems such as shrinking in different proportions.

Working sequence and kneading colors together

1) First of all knead the colored clays separately.

2) Lay them out one on top of the other and knead them together, not too much, otherwise they will blend completely.

3) Slice off a part of the clay, so that you can see to what extent they are mixed.

4) Make your jar remembering that during the throwing and while it is wet, you cannot see the pattern.

5) When finished leave it until it is leather dry, then scrape off the outer skin of clay and you will be able to see the pattern.

6) The clay can be glazed and then fired or first bisque fired and then glazed.

Some clay colors improve greatly with glazing.

CREATING PATTERNS IN COLORED CLAY

1) Draw and plan a design showing: sizes, shapes and colors needed.

2) If a shape has to be repeated many times, cut it out in cardboard, plastic or very fine wood so as to be able to copy it exactly.

3) Roll out the different color clays using slats so they are all the same height.

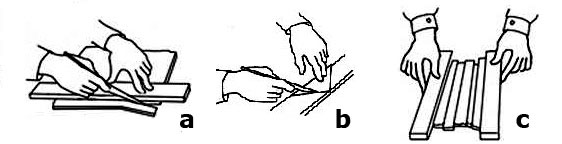

4) Cut them in strips or in the shapes needed. (a) and (b)

5) All the parts that have to be joined should be scored and dampened with slip. When pressed together the slip works like glue. Make slips (clay plus water) from the colored clays being used.

6) On a flat surface lay the different colored strips of clay next to each other and join them by putting a bar of wood on each side and pushing them together. c)

If different shaped pieces are required, roll out the clay into a cylinder to the diameter needed then stand it up, put it between two slats, pull a cutter along the top of the slats, separate the two parts and continue cutting until you have all the pieces needed of the same height. The shapes can then be changed using your fingers or bars to form the shape required.

To make a circle of different colored strips, make a cylinder of the center color. Then roll out flat pieces of different colors. Cut one edge at 45º and then dampen this edge with slip or a soft brush and water. Lay the cylinder of clay on top and parallel to the straight edge and roll the strip round it. Cut off the unwanted clay and join the two sides, then roll backwards and forwards to make sure that it is joined properly and that there are no air bubbles, then go on adding all the colors needed for the design.

Cut the roll of clay into slices, which will be circles of different colored lines then mold them into the shapes required. Agate patterns can be built up to form a flat object such as a tile or a shape using a mold. A mold in two pieces can be used but the places where the two pieces meet must be planned as an integral part of the design. It is easier to use a hump or press mold. Put the prepared pieces into the mold to form the pattern, scoring and using slip to join every piece, pressing them together.

When the clay is in the mold it should be left to dry extremely slowly, to allow the pieces to join and shrink to the same degree. Once hardening starts you can begin, on the inside, to clean it up using a soft rubber kidney or fine sandpaper. When leather-dry it can be removed from the mold without suffering distortion and the outside can then be scraped clean in the same way. When cleaning the outside, always support the inside with your other hand.

Read more about: Molds / Molds-Press Molds / Molds for tiles

Aging in clay is achieved by leaving it untouched for a certain time, so it matures and become more workable. It can be kept in caves, damp rooms, airtight plastic buckets and plastic bags. In the past it was kept in caves for two or more years. Aging lets the dampness penetrate between the particles and gives it a higher plasticity.

ca: PISTOLA D'AIRE - Ceràmica, molles.

es: PISTOLA DE AIRE - Cerámica, moldes.

Click on the title to see more images Air guns expel compressed air and have been adapted for use in the manufacture of pieces made by casting, to speed up the production. They are operated at low pressure round the edge of wet clay in small molds; this slightly dries it and allows the piece to be removed more quickly.

Air guns expel compressed air and have been adapted for use in the manufacture of pieces made by casting, to speed up the production. They are operated at low pressure round the edge of wet clay in small molds; this slightly dries it and allows the piece to be removed more quickly.

They are also used to clean dust from pottery or molds and to apply the glaze.

Read more about: Casting – Dragons

ca: AERÒGRAF – Cerámica, Polvoritzador.

es: AERÓGRAFO – Cerámica, pulverizador.

Click on the title to see more images Airbrush: small gun sprayer using compressed air to spray liquids, colors, glaze-bases, glazes with color, etc. It works the same way as a blow gun and is useful for applying colors delicately in small quantities or areas. There are two types of spray guns.

Airbrush: small gun sprayer using compressed air to spray liquids, colors, glaze-bases, glazes with color, etc. It works the same way as a blow gun and is useful for applying colors delicately in small quantities or areas. There are two types of spray guns.

a) With a suction tank underneath (single action).

There is a push button to activate the flow of air so the paint comes out through the nozzle onto the surface which has to be painted.

b) With gravity tank (double action)

The paint starts to flow when the button is pulled backward and the amount of paint depends on how far you pull the knob.

Note: It is important to clean the airbrush after each use. Follow the instructions that come with it to clean it properly, otherwise the nozzles become clogged.

ca: ALABASTRE

es: ALABASTRO

Alabaster rock is composed of microcrystalline gypsum lens, a fine granular variety of gypsum. It is calcite hard, compact, and is usually a milky translucent white, often with bands of translucent and light colors. It is used for ornamental objects or works such as lamp bases, figurines, jars and ornaments.

ca: ARGILA D'ALBANY

Albany slip is clay that comes from the Hudson River near Albany. It has sufficient fluxes to melt and function as a glaze alumina (Al² O³), an ingredient found in all clays and glazes. Its function is to give greater strength and higher firing temperatures to the body and glaze.

es: ALBARELO - Bote de farmacia

Click on the title to see more images Albarello jars started to be made during the 13th century and were designed for druggists to keep medicinal herbs dry and clean. They were made with lids to help retain the medicinal properties. Decorated with the Latin name of the herb they contained and a drawing of it to help the illiterate public, which at the time was a majority, these jars are still in use in European drug stores as decoration, also in household kitchens to keep spices and herbs for cooking. Over the centuries the lids became damaged or broken so modern ones, made in the antique style, can now be bought with or without lids. The common name for them now is chemist or herb jar.

Albarello jars started to be made during the 13th century and were designed for druggists to keep medicinal herbs dry and clean. They were made with lids to help retain the medicinal properties. Decorated with the Latin name of the herb they contained and a drawing of it to help the illiterate public, which at the time was a majority, these jars are still in use in European drug stores as decoration, also in household kitchens to keep spices and herbs for cooking. Over the centuries the lids became damaged or broken so modern ones, made in the antique style, can now be bought with or without lids. The common name for them now is chemist or herb jar.

The top photo shows two jars made in the classical shape but there are others such as calices and orzas; they are all made in many different sizes.

Read more about: Majolica: 5g – Painting jars / Majolica: 5h – Twelve photos of painted jars

ca: ALCALINS ESMALTS

Alkaline Glaze is one in which the fluxes are alkalis, mainly sodium and potassium. It is the main base for leadless glazes and has a high expansion that leads to crazing; it can be used in crackle glazes and Raku.

ca: ALÚMINI

es: ALUMINA

Aluminum is an important component used to promote stiffness in glazes and increase firing temperatures in clay and glazes, thus helping to unify all the materials and increase their stability. In large quantities it produces opaque and matt effects. It is also used on kiln shelves as protection against glazes adhering to them.

ca: ÀMFORA

es: ÁNFORA

Click on the title to see more images Amphoras are jars that have been found around the Mediterranean coast and were first used in the 15th century BC. They usually have a pointed bottom, can be with or without handles, of any size and have either of two different kinds of neck; one forms a continuous line from the widest part of the body to the final edge; the other differs in that the shoulder of the body curves sharply to join the bottom of the neck. They vary greatly in height from 25cm to 2 meters and were made to store and transport grapes, olives, wine, oil, grains and many other specialties.

Amphoras are jars that have been found around the Mediterranean coast and were first used in the 15th century BC. They usually have a pointed bottom, can be with or without handles, of any size and have either of two different kinds of neck; one forms a continuous line from the widest part of the body to the final edge; the other differs in that the shoulder of the body curves sharply to join the bottom of the neck. They vary greatly in height from 25cm to 2 meters and were made to store and transport grapes, olives, wine, oil, grains and many other specialties.

Originally, an amphora was most probably made using the coiling method and later by wheel, when that started to be used. With a wheel, first the top half was made forming the neck, handles and half the body, that slightly narrowed at the bottom. When this half was finished the clay was left to harden enough to be turned upside down on to a chuck that fitted in to its neck, leaving a space between the edge of the neck and the wheel, so the neck did not take the weight of standing and was not deformed. Then a collar, previously thrown, which had the opening the same size as the base was added to it. It was then turned and the base opened, thinned out and smoothed on both sides to seal the two parts together. The collar was then lengthened and thinned out to a make a point. When the neck was too small for the hand to work inside it, it was pushed together and sealed off on the outside.

ca: ANFÒTER

es: ANFÓTERO

Amphoteric in chemistry, is a substance that can react as either an acid or base. The word is derived from the Greek word amphoteroi meaning “both”. Many metals (such as zinc, tin, lead, aluminum and beryllium) and most metalloids have amphoteric oxides or hydroxides.

ca: ANTIMONI

es: ANTIMONIO

Antimony is a chemical element with the symbol Sb (Latin: stibium) and atomic number 51. A metalloid, antimony has four allotropic forms. The stable form of antimony is a blue-white metalloid. Yellow and black antimony are unstable non-metals. Antimony is used in electronics and flame-proofing, in paints, rubber, ceramics and enamels.

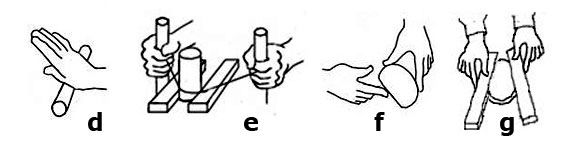

Anvil is a stone or piece of wood that is curved, like an egg. It is held inside a jar against the wall to support the clay and prevent it from breaking while beating on the outside with a paddle. Beating enlarges the jar, thins out the clay and strengthens it.

Anvil is a stone or piece of wood that is curved, like an egg. It is held inside a jar against the wall to support the clay and prevent it from breaking while beating on the outside with a paddle. Beating enlarges the jar, thins out the clay and strengthens it.

Read more about: Paddle

ca: DECORACIÓ APLICADA – Ceràmica, argila.

es: DECORACIÓN APLICADA – Cerámica, arcilla.

Applied decoration denotes clay shapes being added to another clay object. Clay, cut or molded to form a design, is added to another piece of clay. The decoration can be added easily when the clay surface is soft, but once clay is dry, slurry and scoring are necessary. Different methods of shaping can be used: dot box, molding, coiling, sprigging etc. When pieces of clay are put together they must be well sealed to prevent cracks and fractures appearing when drying or being fired. It can be very simple or very complicated as seen in Wedgwood sprigging.

See: Sprigging

ca: APRENENT

es: APRENDIZ

Apprentice is someone who works in a firm or with another person to learn a trade.

Architectural Pottery is work attached to buildings for practical and decorative purposes. They can be tiles, pictures, names, numbers, etc. or work in relief. The photos below show different forms and how these can be mixed with each other and used architecturally.

Architectural Pottery is work attached to buildings for practical and decorative purposes. They can be tiles, pictures, names, numbers, etc. or work in relief. The photos below show different forms and how these can be mixed with each other and used architecturally.

A classical border design used in the decoration of a modern kitchen; a door that at the top shows parts of the town where the business is situated and around the sides, all the plants the firm irrigates; an arch of tiles that separates two rooms; six tiles are used as a picture in the center of a wall; a classic tile picture set in a modern kitchen; biblical scenes made for a church.

Note The tiles in a) to c) are all painted by hand with the Majolica method and g) to i) are industrially made.

Link to Ceramics Bensu for tiles decorated with the Majolica Method

Read more about: Names and notices / Numbers / Repeated tiles

Architectural sculpture is a ceramic design in clay with a flat back, so that when it is finished, it can be attached to a wall or any flat surface. There are two methods; Architectural Sculpture, where both the shapes and levels are in three dimensions and Flat Relief which is at different levels but flat.

The photos in the following three designs show how different techniques can be used together. Next to each design is a map with the layout of the pieces, where they join and how they fit together. All three are made with refractory – stoneware clay, which is strong and good for work that has to be left in the open air. It is clay prepared to retain its physical shape and chemical identity when fired to high temperatures. There are different types made with different textures and colors that can be fired up to 1300º C.

Can Rajoles. Is stoneware, fired at 1300º C, then decorated with colors and fired again at 1280º C. The red of the flag was painted with the on-glaze method and fired at 800º C. Note: In the past the color red could not be fired at a high temperature but it is now made for all temperatures.

Ceramica. Is stoneware, the letters and the background were molded in refractory and fired at 1300º C, then they were painted and all the pieces were fired again at 1280º C. The four plates were painted with the Majolica method and fired at 980º C.

Lleo. Is molded in stoneware in 3 sectionsand is flat but with different heights and fired at 1300º C. The front is covered with an opaque glaze-base using the spattering method then painted with the Majolica method and fired at 980º C.

ca: ARQUITECTURA ESCULTURA - CAN RAJOLES

es: ARQUITECTURA ESCULTURA - CAN RAJOLES

Click on the title to see more images Can Rajoles means the house of tiles in Catalan and St. George is the Patron Saint of Catalonia. The work is formed in refractory in 20 separate pieces and is 46in long and 38in high (130 × 100cm). It was bisque fired at 1300º C, then decorated with colors that vitrify at 1280º C and fired again.

Can Rajoles means the house of tiles in Catalan and St. George is the Patron Saint of Catalonia. The work is formed in refractory in 20 separate pieces and is 46in long and 38in high (130 × 100cm). It was bisque fired at 1300º C, then decorated with colors that vitrify at 1280º C and fired again.

The red was then added to the stripes on the flag and this one piece was fired at 800º C.

ca: ARQUITECTURA ESCULTURA - CERÀMICA

es: ARQUITECTURA ESCULTURA - CERÁMICA

Click on the title to see more images The work consists of seven pieces: the word ceramica is in three (CE/ RAM/ ICA), and there are four more, each a plate with background. The slight overlapping of the letters hides the places where the pieces join. It was all molded in refractory and bisque fired at 1300º C. Then the letters and the background were decorated with oxides that vitrify at 1280° C and fired again. After this, the plates were decorated using the Majolica method and finally these four sections were fired at 980º C.

The work consists of seven pieces: the word ceramica is in three (CE/ RAM/ ICA), and there are four more, each a plate with background. The slight overlapping of the letters hides the places where the pieces join. It was all molded in refractory and bisque fired at 1300º C. Then the letters and the background were decorated with oxides that vitrify at 1280° C and fired again. After this, the plates were decorated using the Majolica method and finally these four sections were fired at 980º C.

Working sequence

a) When sculpturing with clay, first make a design on paper. Work out where the outlines of the different pieces will join in relation to the design and take into account the width of the pieces, making sure they will fit into the kiln when laid out on the shelves for firing.

b) Cut out in paper the shapes that are needed.

c) Use a table you can walk or turn round and work on top of a large piece of wood covered with a material; canvas is very good for this.

d) Knead, roll out the clay to the height needed and cut it into the required sizes following the outline of the paper.

e) Build up and carve away the clay following your original design, making the parts fit together correctly and overlap if you want to hide the joints.

f) In the drawings next to the three photos the outlines of the separate pieces are shown but in the finished work many are completely hidden by the overlapping of other parts of the design.

g) Keep advancing at the same stage and with the same plasticity, so the shrinkage is even.

h) When not working cover it with a damp cloth and a sheet of plastic and don’t let one part dry more than another. Take into account that a piece that varies in thickness will dry quicker in the thinner parts, which can lead to breaking.

i) As the work progresses let it dry off slightly. This makes it easier to add details and to smooth out. Gradually build up your design adding and changing ideas, leaving textures and finishing off smoothly where needed.

j) If they are large heavy pieces scrape out some of the clay from behind when finished. This makes them lighter and helps the drying process. On the back, indent lines to help it adhere when attached to a wall.

k) When the work is finished it will have changed from the original drawing. If it is complicated, redraw the outlines and number them, then indent each piece on the back with the relevant number.

l) When finished leave your work uncovered to dry, keeping it weighed down so the edges cannot warp upwards. Use small objects like ashtrays, weights, pots etc., and put them round the edges and places you think are more likely to bend.

m) During the drying period keep cleaning and tidying your work, altering parts if necessary to make them fit together perfectly

n) When completely dry proceed to firing them. As there are parts that are thicker than others it is very difficult to know if they are completely dry inside. For this reason start firing very slowly and at a low temperature for a long time. This is to give the thick parts time to dry out. I let the kiln take 4 hours to heat up from 0º C to 600º C, after which it takes about 6 hours to reach 1300º C.

o) Fire refractory clay at 1300º C. It can be decorated with colors that vitrify at different temperatures always starting with the highest of 1280º C and then decreasing.

ca: ARQUITECTURA ESCULTURA - LLEÓ

es: ARQUITECTURA ESCULTURA - LLEO

Click on the title to see more images

Lleo consists of three pieces molded in refractory and fired at 1280º C, then decorated following the Majolica method and fired at 980º C. The lion and the background are in one piece and flat but at different levels, there is a variation of ½in (2cm), the letters “LL” and “EO” are in relief.

Working sequence

Flat Relief: is a design with different layers of flat clay.

a) Roll out the clay to the height needed.

b) Cut out the shapes needed. In Lleo there are three pieces.

c) Mark the outline by laying the design on top of the clay and with a pencil, mark round the outline indenting it into the clay.

d) Scrape and sliver off the lower parts to make the different levels.

e) Model and tidy up the edges to the exact shapes you need. Here it is in two levels, but this depends on your design requirements. When dry it was fired at 1280º C.

Decorating:

The glaze-base has been put on with a texture called shacking.

Stir the base that is in your base container, take out a bowlful and put it to one side, add water to the base until it is very thin, then stir it well.

Prepare the three pieces in the following way, one by one. Hold one upside down and dip it into the base just deeply enough to cover the front and sides but not the back, so that the base goes in between the angles. Move it from side to side, lift it out and turn it round. With a brush made with palm leaves, dip the leaves into the thick glaze that has been kept and shack it over the thin glaze, leaving the surfaces with a texture.

With a paintbrush drip more glaze over the letters and lion and with a wet brush smooth it down.

Clean the base off the backs but leave it round the sides, then paint the letters and the lion and fire it at 980º C.

ca: CENDRA - Utilitza en la ceràmica.

es: CENIZA - Utiliza en la cerámica.

Ash is the powder left after the combustion of any material. The ashes used in pottery are natural, made from trees, plants and animal bones and these can be bought prepared as very fine powder. You can make charcoal powder by burning down boxes such as those used for packing fruit and vegetables. The ash must be broken down into a fine powder, sieved to take out all the rough bits. Cover it with water and pass it through a sieve with a fine mesh, repeat this several times, then lay it out on a flat surface to dry. When dry store it in an airtight jar.

In pottery charcoal powder is used to mark out the outlines of designs. The design should be on transparent paper and pounced, laid on top of what is being decorated and rubbed with a small bag full of ash, which goes through the holes and marks on the design. As charcoal powder is a natural product it will burn away when fired at 700º C. and for this reason, when pieces are fired at 980º C., the remainder of the product will then disappear.

As ashes form part of a glaze and are easily melted, their function is also to help to bring the firing temperature down and create transparent effects.

Read more about : Charcoal – Powder / Marking / Marking – Bag for charcoal / Marking Tiles – Large designs / Marking Tiles – Small designs

ca: CENDRER

es: CENICERO

Click on the title to see more images Ashtray is a plate that varies in size, is usually about 20 cm or smaller in diameter and can be any shape, round, square, etc.

Ashtray is a plate that varies in size, is usually about 20 cm or smaller in diameter and can be any shape, round, square, etc.

The outer edges slant upward very slightly, they can be with or without borders and the edges have open half circles to hold cigarettes. They are made to hold the ash that is thrown off while smoking.

ca: ATMOSFERA

es: ATMÓSFERA

Atmosphere is the air that surrounds ceramic work while drying or being fired and its temperature can affect the speed of drying.