CLAY - Drying.

Dry clay if it is too wet to be used; the water can be absorbed by wedging and kneading on wood or cloth. Keep turning the wood and changing the cloth so what you are working on is dry.

a) If the clay is in a very liquid state, spread it onto a large flat container, leave to settle down so the water dries out. When thick enough to move, lay it on top of a cloth which is on top of a movable wooden board. Leave to dry for a while and then put another dry cloth and a dry piece of wood on top, turn it over, using the two bits of wood as a sandwich. Take off the damp cloth and board, which are now on top and repeat this until it becomes dry enough to knead.

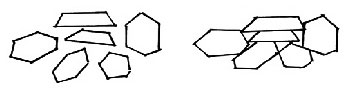

b) Before firing, all clays should be thoroughly dried out. If not dry enough the dampness can form an uneven heat and cause it to crack, break or deform. The following drawings are to give an idea of how the process of drying works.

The water migrates from the center, through the pores to the surface and the particles close more on the outside where it is dryer. As this happens it becomes more difficult for the water to move outwards and this slows up the drying process. If the work is a plate or jar where the walls are thin, there are fewer problems but if thick, such as work in relief, it is very difficult to know how dry it is and for this reason the first hours of firing should be at a low heat and for a long time.