SCREEN PRINTING - In pottery (6) Printing onto tiles.

ca: SERIGRAFIA - En ceràmica (6) Impressió.

es: SERIGRAFÍA - En cerámica (6) Impresión.

Screen Printing

Screen Printing

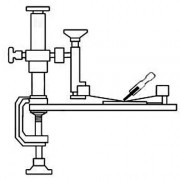

a) The tiles have been placed in relation to the screen. You must check that the space between the screen and the tiles is correct when it is pulled down.

b) Put bits on the table to support the front two corners of the screen so it rests on them when pulled down. Pull it down and hold it so it touches the bits on both sides, look between the screen and the tiles, there should be a parallel space of about ½cm between them. Adjust this by turning the knobs until it is correct.

c) Side view, to show that the mesh only touches the tile while the squeegee is being used.

Note: This can become complicated if the wood of the frames warp with age or the business that makes the screen has not placed the design parallel to the frame.

d) Slightly lift the frame, dip the big paint brush into the paint and put a line of it along the back, without touching the design.

e) Lower it without touching the tiles, move the squeegee pulling the paint over the screen from the far side to the near side.

f) Move the excessive paint at the top to the right and then to the bottom.

g) Pull down the frame and hold it down with your left hand and with your right pull the squeegee over the screen, keeping it at 45º. Do it several times until the outlines are completely covered. Lift up the screen and move the excess paint to the right and then down to the bottom placing it for the next printing.

h) The printing finished.

i) Lift them up the tiles, on the back paint the number and code and then put them separately on the shelves to dry.

Chiropodist and builder

The first tile shows the outlines and the next is painted and fired.

Note: There is another way to print the tiles; the screen is laid and held down, the paint is added in the same way and then pulled directly over the screen.

SCREEN PRINTNG – USEFUL TIPS

1) It can be done in two or three movements either length or width wise.

2) The paint being used must have the right density and be well mixed.

3) If you are printing designs of more than one tile, as the edges are slightly curved pull the squeegee over the part where they connect without adding any more paint.

4) The screen can get blocked while working for various reasons, the glaze base can be too damp or too dry or the screen too close to the tiles.

5) When the screen is blocked, do not dismount it. Have a basin with clean water, a cloth and a roll of hand paper. Clean it on both sides and the front that touches the tiles must be dry it can be used.

The next section; Screen Printing (7) Big screens