KILN (1) Gas for pottery.

es: HORNO (1) Gas por cerámica

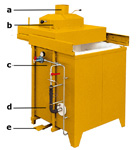

1) Gas kiln: It is square, packed and opened from above. The lid is opened by pressing a pedal with your foot, and pulled outwards horizontally over two guides. It has two burners and the ventilating hood is on top of the kiln with a handle which allows the opening or closing of the entrance of air when firing is being reduced.

1) Gas kiln: It is square, packed and opened from above. The lid is opened by pressing a pedal with your foot, and pulled outwards horizontally over two guides. It has two burners and the ventilating hood is on top of the kiln with a handle which allows the opening or closing of the entrance of air when firing is being reduced.

a) The kiln chimney. b) A sliding lid at the top, c) The gas controller. d) Nozzle to the gas burner with air controller. e) A pedal at the bottom to open the sliding door at the top

2 – 3) Gas kiln: It is round and packed from above. The top part is a lid that has a ventilating hole and above it is the hood; they are separated but attached by a small metal bar on each side and it has two burners. The vent hole has a handle to open or close the entrance of air.

The lid can be lifted and moved horizontally by pressuring your foot on top of the pedal which is underneath the kiln

4) Gas kiln the system is the same as 2 & 3 and it is still fabricated.

5) Gas kiln: A square one with a door at the front, the burners are placed at two lateral parts of the kiln and there are three for each side, the chimney and a ventilating hood are attached to the top with a handle for opening and closing the entrance of air.

Note: When used the ventilating hood or chimney are connected to a tube that goes outside. It can have a suction fan to draw out and expel the combustion of toxic gas, fumes and odors that have been created during the firing.

These kilns are made to be controlled manually or automatically and usually their maximum temperature is 1300º C.