RAKU

ca: RAKU

es: RAKU

*Raku,*is an oriental technique dating back to the 16th century. It is believed to have originated in Korea but it prospered in Japan and has extended throughout the world, it was originally created for the tea ceremony. The word Raku means “happiness”. It is a method of creating effects with colors and textures either by the use of enamels or simply with smoke, it involves rapid firing and rapid cooling while still red hot from the kiln. The clay used for Raku must be prepared with a high percentage of sand or grog to withstand the rapid and extreme changes of temperature. The clay to be used should be chosen with care to avoid the risk of breakage.

*Raku,*is an oriental technique dating back to the 16th century. It is believed to have originated in Korea but it prospered in Japan and has extended throughout the world, it was originally created for the tea ceremony. The word Raku means “happiness”. It is a method of creating effects with colors and textures either by the use of enamels or simply with smoke, it involves rapid firing and rapid cooling while still red hot from the kiln. The clay used for Raku must be prepared with a high percentage of sand or grog to withstand the rapid and extreme changes of temperature. The clay to be used should be chosen with care to avoid the risk of breakage.

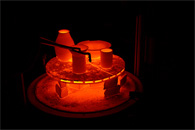

The firing of the enamels is done in gas or wood fired kilns. Raku enamels and colors are fired from 800º to 1000º C with a rapid firingx to reach the right temperature in 15 to 30 minutes, then the kiln is opened and the red hot piece is taken out.

The piece is taken out of the kiln and exposed to the air then put into a metal bucket half full of sand or dry leaves for a short while, just long enough for the reduction and the smoke to penetrate into the piece, transforming the colors and enhancing the crackled enamel effect produced by the heat crash, a common characteristic of this enamel technique. Next it is rapidly cooled down in another bucket full of water and the smoke stuck to the enamel is washed off at the same time.

Besides the finishes achieved with classic enamels, both shiny and crackled, we also have the naked or lost enamel Raku technique, whereby an engobe that does not bond well to the piece is used, causing the enamel to come off at the end of the process leaving only the patterns made by the smoke. The patterns can be left to chance (crackled) or designed by the ceramist.

Another technique is known as the “matt copper” technique. By using an enamel supersaturated with copper, we can achieve a matt finish together with the wide range of colors that copper develops in a reducing atmosphere.

The kiln can be loaded from the top or from the front, although the most recommended type is the one designed so that the body of the kiln is lifted up by pulleys and the fired pieces remain on the floor and so are easy to handle. This procedure produces smoke, so it must be done in the open air. To get the pieces out of the oven you must use long tongs and protect yourself with protective glasses and heatproof gloves.