SLIP CASTING

Slip casting is a method for the mass-production of pottery. Its greatest advantage is that an exact shape can be repeated hundreds of times. It is especially good for shapes not easily made on a wheel, like plates with very low borders. Most of the pottery figures found in the shops are cast.

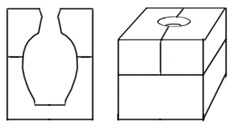

Slip or liquid clay is poured into a plaster mold, plaster absorbs water so as it reduces, layers of clay build up against the inside walls of the mold. When most of the liquid has been absorbed what remains is poured off. It is left to dry and when drying it shrinks, so that when opened it is easy to remove. Where the parts of the mold join an uneven surface will have been left which will have to be trimmed. The product is left to dry and when dry it becomes what is known as green ware. It can then be decorated with a transparent glaze or colored slips, the two can be fired together or it can be fired and then decorated and fired again.

Link to Slip Casting in Basic-Stuff.

To see how a mold is used. Casting dragons