TABLE - Glaze-Bases

es: MESAS - Para Esmaltes Bases

Click on the title to see more images Tables, basins, shelves for working with glazes.

Tables, basins, shelves for working with glazes.

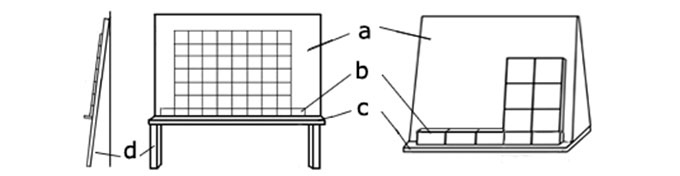

This table is designed for storing three different glaze-bases and for applying them to all types of ware; tiles, plates, jugs and lids. When making the table, remember it must be low enough to allow space for your arm to move over the basin when throwing the glaze-base onto tiles.

The size of the piece of furniture depends on where it is going to be, how many glazes you want to have permanently prepared and on the size of the products you decorate. The one that is described here has three plastic containers of different sizes, each a different color. The center shelves must be very strong, to take the weight of the containers full of liquid glaze-base, prepared for use. The inside measurements of the big basin are about 60 cm wide and 30 cm deep and the two small ones are 42 cm wide and 30 cm deep. In the small ones I keep crackle and semi-matte glaze-base. The big one holds about 30kg of Siglo 18, all ready to use.

Each of the three containers must have a separate lid to keep the glazes clean. They are made to fit together so they form a large tabletop, which is a useful space to work on. The wooden bar round the outer edge of the table supports each lid on one or two sides. On the undersides of each lid, bars the same height as the ones round the edge of the table, are attached on the front and sides that need support.

On the wall above the table, mount as many removable shelves as possible. There are two different widths, 15cm and 20cm, which are the width of the tiles. These are to leave work that has been prepared with a glaze-base to dry, before starting to clean it. When preparing jars or plates just take out a few shelves, put one on top of the other and you’ll have the space needed for them height wise.

The bottom shelf of the table should be high enough to make cleaning underneath easy with a broom, mop or vacuum cleaner. Boxes can be made with lids and wheels to fit into these spaces and used to store products.

The sections on containers.

a) Bars to support the shelves.b) Movable shelves to support prepared work.

c) Bars to support the lids. d) Containers with different glaze-bases. e) Glaze. f) Strong shelves to hold the containers. g) Shelves. h) Lids to cover each container separately.

Read more about: Container – Glaze-base / Glaze-base (e) Applying by pouring on to tiles

This is a table set up like a shelf, it is designed so three people can sit and paint at the same time. Underneath it has room for a

This is a table set up like a shelf, it is designed so three people can sit and paint at the same time. Underneath it has room for a  Table -Trolley to hold everything you need while working; it should have wheels as you could be working on two or three different pieces at the same time and it makes moving about easier. What makes an excellent table is a bedside table. It is the right height and if it has three or four drawers, take one or two out so as to make shelves. Put wheels on it so it is easy to move and use it for painting, sitting or standing. In the three photos the first is a doctor’s table designed to hold instruments and the next are bedside tables.

Table -Trolley to hold everything you need while working; it should have wheels as you could be working on two or three different pieces at the same time and it makes moving about easier. What makes an excellent table is a bedside table. It is the right height and if it has three or four drawers, take one or two out so as to make shelves. Put wheels on it so it is easy to move and use it for painting, sitting or standing. In the three photos the first is a doctor’s table designed to hold instruments and the next are bedside tables.  Tables with tiles: If they are for indoor usethe tiles can be supported by a wooden frame but for outdoor use, metal and plaster should be used.

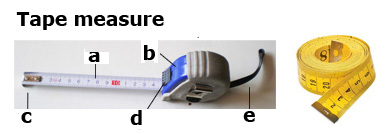

Tables with tiles: If they are for indoor usethe tiles can be supported by a wooden frame but for outdoor use, metal and plaster should be used.  Tape measure is a long and flexible strip of cloth or metal, marked in subdivisions of centimeters or inches and used to measure spaces. When flexible it is known as a tape measure and when not flexible it is a

Tape measure is a long and flexible strip of cloth or metal, marked in subdivisions of centimeters or inches and used to measure spaces. When flexible it is known as a tape measure and when not flexible it is a  Teapot is a utensil for soaking tea leaves or herbal mixtures in boiling water. It has a lid, a handle, and a funnel which has a straining section.

Teapot is a utensil for soaking tea leaves or herbal mixtures in boiling water. It has a lid, a handle, and a funnel which has a straining section. Method of working: To form the main body of a teapot,

Method of working: To form the main body of a teapot,  Method of working: When the shape of the body has been formed, open the neck a little to the size you require for the lid. With a

Method of working: When the shape of the body has been formed, open the neck a little to the size you require for the lid. With a  Method of working: Start as explained in the previous section, leaving the neck bigger so a

Method of working: Start as explained in the previous section, leaving the neck bigger so a

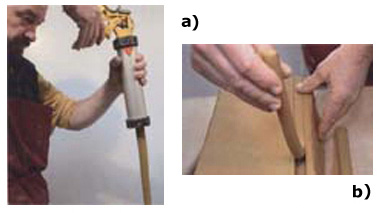

Pulling a handle. Make the clay into a cone shape, hold it with one hand and pull it down with the other that is wet. The movement must be smooth and continuous to avoid it breaking. As you lengthen it, start giving it a shape, round, rectangular or triangular.

Pulling a handle. Make the clay into a cone shape, hold it with one hand and pull it down with the other that is wet. The movement must be smooth and continuous to avoid it breaking. As you lengthen it, start giving it a shape, round, rectangular or triangular.  Extruders a) and coiling b) are both used for making handles and are explained in these sections;

Extruders a) and coiling b) are both used for making handles and are explained in these sections;  Turning handles on the wheel, first form a big cylinder, making the circumference bigger than the length you will need for the handle. Decide on the width you require and mark the height. When it is formed cut it with a saw blade to separate it from the cylinder.

Turning handles on the wheel, first form a big cylinder, making the circumference bigger than the length you will need for the handle. Decide on the width you require and mark the height. When it is formed cut it with a saw blade to separate it from the cylinder. Method of working

Method of working  Teaspoon is a small spoon designed to add and mix sugar with a cup of tea and has got its name from this function.

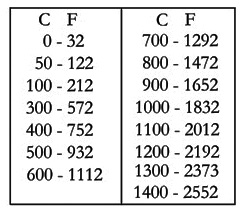

Teaspoon is a small spoon designed to add and mix sugar with a cup of tea and has got its name from this function.  Temperature: there are two main scales of temperature, Centigrade (º C) and Fahrenheit (º F). All the temperatures in this dictionary are given in Centigrade; the following is a conversion table of Centigrade to Fahrenheit.

Temperature: there are two main scales of temperature, Centigrade (º C) and Fahrenheit (º F). All the temperatures in this dictionary are given in Centigrade; the following is a conversion table of Centigrade to Fahrenheit.

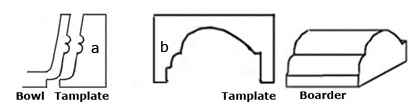

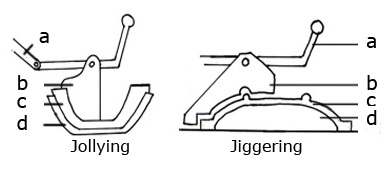

By jolly or jigger: They are instruments made to hold a template in relation to the clay being turned on the wheel. They must be very stable and for this reason are usually attached to a wall. A mold is put on to a wheel and centered, the clay laid over it or into it. The template is held in a jigger or jolly, placed against the clay then the wheel is slowly turned and the template scrapes and removes the unnecessary clay until it forms the shape of the template.

By jolly or jigger: They are instruments made to hold a template in relation to the clay being turned on the wheel. They must be very stable and for this reason are usually attached to a wall. A mold is put on to a wheel and centered, the clay laid over it or into it. The template is held in a jigger or jolly, placed against the clay then the wheel is slowly turned and the template scrapes and removes the unnecessary clay until it forms the shape of the template. Tenmoku is the Japanese word for a type of tea bowl made first in China during the Sung dynasty (960-1279). Tenmoku glazes are easily recognizable. The enamels are dark, from reddish browns to dark browns and blacks, produced by a high iron content. Ash is usually incorporated as a flux.

Tenmoku is the Japanese word for a type of tea bowl made first in China during the Sung dynasty (960-1279). Tenmoku glazes are easily recognizable. The enamels are dark, from reddish browns to dark browns and blacks, produced by a high iron content. Ash is usually incorporated as a flux. Terracotta is red-brown clay that has been fired. It is the most common clay, found in the earth throughout the world. It can be molded, cast and turned on the wheel and used to make bricks, tiles, flower pots and many objects, both industrial and decorative. It is cheap, easy to work with; it is formed into a required shape, left to dry and then fired at between 800º C and 1050º C. When fired it turns into a material that is solid and breakable but still porous. It is not waterproof, water can dampen and pass through it but without altering its structure and when fired it is also known as bisque. To make it waterproof, it must be covered with a layer of glaze and fired again, the glaze vitrifies and acts as a thin layer of glass and makes it non-absorbent. Read more about:

Terracotta is red-brown clay that has been fired. It is the most common clay, found in the earth throughout the world. It can be molded, cast and turned on the wheel and used to make bricks, tiles, flower pots and many objects, both industrial and decorative. It is cheap, easy to work with; it is formed into a required shape, left to dry and then fired at between 800º C and 1050º C. When fired it turns into a material that is solid and breakable but still porous. It is not waterproof, water can dampen and pass through it but without altering its structure and when fired it is also known as bisque. To make it waterproof, it must be covered with a layer of glaze and fired again, the glaze vitrifies and acts as a thin layer of glass and makes it non-absorbent. Read more about:  ———

———

Throwing a plate using a tube.

Throwing a plate using a tube. They are flat simple slabs of clay, earthenware, stoneware and porcelain made up in hundreds of different styles, shapes and thicknesses, handmade, semi handmade or industrially produced and can be used to cover interior or exterior structures in buildings for floors, walls, pictures, names and numbers and general decoration. Made to form patterns that have one or more tiles with proportions so they fit together to form a flat, continuous surface. On the back they are always flat and the designs on the front can be in relief.

They are flat simple slabs of clay, earthenware, stoneware and porcelain made up in hundreds of different styles, shapes and thicknesses, handmade, semi handmade or industrially produced and can be used to cover interior or exterior structures in buildings for floors, walls, pictures, names and numbers and general decoration. Made to form patterns that have one or more tiles with proportions so they fit together to form a flat, continuous surface. On the back they are always flat and the designs on the front can be in relief.  Tiles: When odd shapes are needed tiles can be made by hand or industrially and can be cut down altering their size and shape, but if many are needed you must make a mold. There are special cutters, made to cut curved parts; but they are a luxury not many people can afford or need. For cutting straight lines go to these sections and follow the instructions;

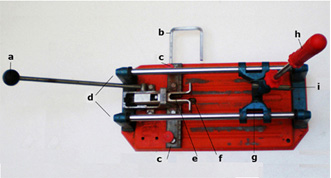

Tiles: When odd shapes are needed tiles can be made by hand or industrially and can be cut down altering their size and shape, but if many are needed you must make a mold. There are special cutters, made to cut curved parts; but they are a luxury not many people can afford or need. For cutting straight lines go to these sections and follow the instructions;  Cutting a tile; mark the lines on the tile where it has to be cut. It measures 15×15cm and can be used to make two bars of different widths, each one will have an uncut straight side of the tile which makes it stronger. With a pencil draw lines for the two sizes needed, the one on the left is 1cm and will be cut first and the one on the right is 2cm. Cut through half the tile that is going to be used, about 4cm from the drawn line and parallel to it, turn it and cut the other half, so it separates.

Cutting a tile; mark the lines on the tile where it has to be cut. It measures 15×15cm and can be used to make two bars of different widths, each one will have an uncut straight side of the tile which makes it stronger. With a pencil draw lines for the two sizes needed, the one on the left is 1cm and will be cut first and the one on the right is 2cm. Cut through half the tile that is going to be used, about 4cm from the drawn line and parallel to it, turn it and cut the other half, so it separates. Cutting round curves; with the electric tile cutter make enough space for the tile to be flat and moved at any angle, always work with the face of the tile upwards. With a lead pencil, draw the outline of the circle on the tile. Start cutting off a small section from a corner, the first one can be done in one piece but when the part to be cut becomes long, cut the corners off in small pieces. After the first corner is cut off, do the same with the other three.

Cutting round curves; with the electric tile cutter make enough space for the tile to be flat and moved at any angle, always work with the face of the tile upwards. With a lead pencil, draw the outline of the circle on the tile. Start cutting off a small section from a corner, the first one can be done in one piece but when the part to be cut becomes long, cut the corners off in small pieces. After the first corner is cut off, do the same with the other three.  Tile, cutting corners off. First, draw the outlines of the straight lines that have to be cut off to make the square smaller, to the size required. Move the wall of the cutter, so the tile can be flat and it can be turned round; remember always to cut with the good side upwards. Two sides are used and two sides and four corners have to be cut off.

Tile, cutting corners off. First, draw the outlines of the straight lines that have to be cut off to make the square smaller, to the size required. Move the wall of the cutter, so the tile can be flat and it can be turned round; remember always to cut with the good side upwards. Two sides are used and two sides and four corners have to be cut off.  Cutting out curves. To cut this tile, as the design is smaller than the tile, two sides have to be cut off and then the required shape is cut out. In the past this shape was commonly used is Spain. As large amounts were needed they were made with a mold, now as only one has got to be made, it is quicker to cut down a tile to the correct shape.

Cutting out curves. To cut this tile, as the design is smaller than the tile, two sides have to be cut off and then the required shape is cut out. In the past this shape was commonly used is Spain. As large amounts were needed they were made with a mold, now as only one has got to be made, it is quicker to cut down a tile to the correct shape. All these photos were taken in the Museu Municipal Vicenç Ro, in Martorell, Catalonia. It specializes in collecting and restoring all types of antique pottery, tiles, plats, jars, etc. It is open to the public by appointment, one person can go, you do not have to go with a group.

All these photos were taken in the Museu Municipal Vicenç Ro, in Martorell, Catalonia. It specializes in collecting and restoring all types of antique pottery, tiles, plats, jars, etc. It is open to the public by appointment, one person can go, you do not have to go with a group.  Border is the decoration that goes round the edge of an object. With plates, jars and lids the border is always part of the piece but with work in relief and tiles it can be part of it or completely separated. In the following sections on borders, all types are covered.

Border is the decoration that goes round the edge of an object. With plates, jars and lids the border is always part of the piece but with work in relief and tiles it can be part of it or completely separated. In the following sections on borders, all types are covered.  Tiles – broken and cracked.

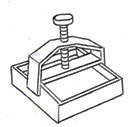

Tiles – broken and cracked. Tile – Clay cutters are made in metal to cut out different geometrical shapes and sizes in flat clay, some of which can fit together to form a flat surface. The clay is rolled out to the required height, the cutter is laid on top, the walls, controlled by a spring, are pushed down into it and the shape is cut out.

Tile – Clay cutters are made in metal to cut out different geometrical shapes and sizes in flat clay, some of which can fit together to form a flat surface. The clay is rolled out to the required height, the cutter is laid on top, the walls, controlled by a spring, are pushed down into it and the shape is cut out. The parts of the tile cutter:

The parts of the tile cutter: Tile – Electric tile cutter

Tile – Electric tile cutter  Tiles for decorating

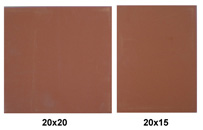

Tiles for decorating  In the past there were many different types of industrially made tiles with different trademarks, qualities, sizes and colors. Their production was carried out in two stages: the making of the bisque and the decoration, often by two different firms. The way of producing tiles in the last 60 years has completely changed, they are now made with non-stop machinery which shapes, dries, decorates and fires them and they are made to be stronger, lighter and cheaper. There are still a few firms which specialize in the fabrication, so the choice has become limited and the ways used have changed, affecting the Majolica method.

In the past there were many different types of industrially made tiles with different trademarks, qualities, sizes and colors. Their production was carried out in two stages: the making of the bisque and the decoration, often by two different firms. The way of producing tiles in the last 60 years has completely changed, they are now made with non-stop machinery which shapes, dries, decorates and fires them and they are made to be stronger, lighter and cheaper. There are still a few firms which specialize in the fabrication, so the choice has become limited and the ways used have changed, affecting the Majolica method.  Tile shelves, are industrially made bisque tiles cut down to the sizes you require for shelves, to be used when packing the kiln and as a tray to move decorated work. As the work cannot be touched, the tile is used like a tray to move it from the place it has been decorated to the kiln, where it becomes a shelf supported by tube props.

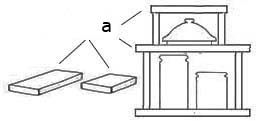

Tile shelves, are industrially made bisque tiles cut down to the sizes you require for shelves, to be used when packing the kiln and as a tray to move decorated work. As the work cannot be touched, the tile is used like a tray to move it from the place it has been decorated to the kiln, where it becomes a shelf supported by tube props.

1) When tiles are decorated to be used in public places and attached to a wall that is outside, every inch it covers must have cement, so there are no spaces left between them. If a space is left and they are hit by strong article, like a ball or a ladder, they will break where the tiles have no support. Some have been placed on a building many years ago and they are very difficult to remove, nearly impossible, because the cement they have been attached with is so strong, when being separated they break.

1) When tiles are decorated to be used in public places and attached to a wall that is outside, every inch it covers must have cement, so there are no spaces left between them. If a space is left and they are hit by strong article, like a ball or a ladder, they will break where the tiles have no support. Some have been placed on a building many years ago and they are very difficult to remove, nearly impossible, because the cement they have been attached with is so strong, when being separated they break.  1) Occupations are one tile designs that illustrate different ways of working.

1) Occupations are one tile designs that illustrate different ways of working. Tiles you can decorate with different methods for decorative or practical purposes . It can be a picture of your choice, numbers, names and repeated tiles that are modern or copies of antique designs. The great advantage of using tiles, if the finished work has been well installed, they can last forever,

Tiles you can decorate with different methods for decorative or practical purposes . It can be a picture of your choice, numbers, names and repeated tiles that are modern or copies of antique designs. The great advantage of using tiles, if the finished work has been well installed, they can last forever,  Tongs: are metal instruments used for picking up fired pieces and removing them from the kiln while still hot. They are also made with a much wider opening for holding large plates, pots, lids and other objects when dipping them into a glaze-base or color.

Tongs: are metal instruments used for picking up fired pieces and removing them from the kiln while still hot. They are also made with a much wider opening for holding large plates, pots, lids and other objects when dipping them into a glaze-base or color.  Toothbrush is a small brush with a long handle used for cleaning teeth. When old, hard and cut down they are good for cleaning small places and footings of plates, jars and lids It is very important that the footings are clean so they do not adhere to what they are standing on when being fired.

Toothbrush is a small brush with a long handle used for cleaning teeth. When old, hard and cut down they are good for cleaning small places and footings of plates, jars and lids It is very important that the footings are clean so they do not adhere to what they are standing on when being fired. Trailing is to apply a color, held in a small container, by pushing it down and out through a nozzle to trail in a continuous line. For this a slip trailer, injection tube or a bag for icing cakes can be used. They can be bought with different sized nozzles.

Trailing is to apply a color, held in a small container, by pushing it down and out through a nozzle to trail in a continuous line. For this a slip trailer, injection tube or a bag for icing cakes can be used. They can be bought with different sized nozzles. Trailing can be done on to clay or bisque directly or by first covering what is being decorated with a color and then trailing other colors on top, using a slip trailer. The lines of different colors can be broken in irregular ways like feathering, tilting. Trailing can used to fill up spaces, draw outlines and to write.

Trailing can be done on to clay or bisque directly or by first covering what is being decorated with a color and then trailing other colors on top, using a slip trailer. The lines of different colors can be broken in irregular ways like feathering, tilting. Trailing can used to fill up spaces, draw outlines and to write. Transfer literally means to pass something from one place to another. A transfer in ceramics is a design copied industrially to be reproduced many times. They are printed on specially prepared paper to form a film that can be transferred onto another surface, they can be bought prepared or you can have a design made.

Transfer literally means to pass something from one place to another. A transfer in ceramics is a design copied industrially to be reproduced many times. They are printed on specially prepared paper to form a film that can be transferred onto another surface, they can be bought prepared or you can have a design made.  The names of the parts of a tripod.

The names of the parts of a tripod. Trolley for a potter consists of shelves with wheels. There are different types, some can be folded, some have selves that can be taken off and moved up and down to accommodate work of all sizes. They are very useful for moving and storing decorated work.

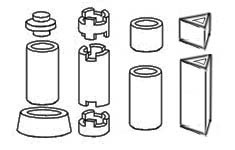

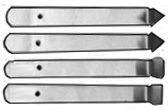

Trolley for a potter consists of shelves with wheels. There are different types, some can be folded, some have selves that can be taken off and moved up and down to accommodate work of all sizes. They are very useful for moving and storing decorated work.  Tube props: are kiln furniture. They are legs used for supporting and building up space between shelves and are made in many different shapes and sizes. The first two from the left are designed so they lock into each other and the last two are straight and have to be well balanced. As the shelf is put on top of them, the weight helps to hold them in place.

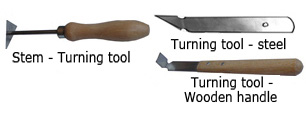

Tube props: are kiln furniture. They are legs used for supporting and building up space between shelves and are made in many different shapes and sizes. The first two from the left are designed so they lock into each other and the last two are straight and have to be well balanced. As the shelf is put on top of them, the weight helps to hold them in place. Turning tools: made of steel are strong and have cutting edges that can be sharpened. They are made in four shapes round, square, triangle and leaf. They are mainly for turning but can be used in many other ways such as for carving clay and plaster.

Turning tools: made of steel are strong and have cutting edges that can be sharpened. They are made in four shapes round, square, triangle and leaf. They are mainly for turning but can be used in many other ways such as for carving clay and plaster.  Turning tools that are steel, strong, with cutting edges that can be sharpened it is made in four shapes round, square triangle and leaf.They are mainly for turning but can be used in many other ways such as carving clay and plaster.

Turning tools that are steel, strong, with cutting edges that can be sharpened it is made in four shapes round, square triangle and leaf.They are mainly for turning but can be used in many other ways such as carving clay and plaster.  Turning tools with wooden handles, the head is flat steel with the top bent outwards and with different shaped points square, round, triangle and leaf. They are mainly for turning but can be used in many other ways such as in carving clay and plaster.

Turning tools with wooden handles, the head is flat steel with the top bent outwards and with different shaped points square, round, triangle and leaf. They are mainly for turning but can be used in many other ways such as in carving clay and plaster.